Kuozhan in Henan, the first PET “Dark Factory“ in China

Using DataBeyond IQC Line of Plastic Bales

01

Automated, Intelligent, and Digital QC Check

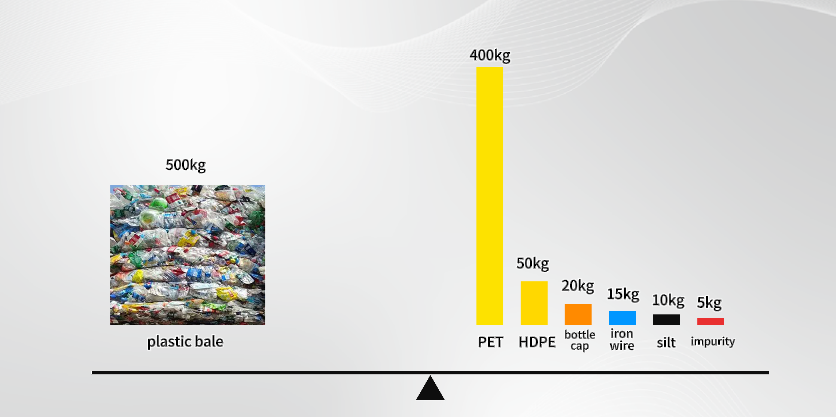

Analyze the proportion data of the weight of various plastics and residues

Incoming materials arrive at the factoryy, from weighing to output ratio, bottle bales can be customized according to demand to detect content such as material, color, oil bottles, wide-mouth bottles, aluminum bottles, and residues (sand, metal, water-containing bottles, paper-containing bottles, iron wires, etc.). Through data analysis, a reasonable price for the bottle bales can be set, avoiding payment for impurities and making the cost of incoming materials clear at a glance.

02

Reduce Cost And Increase Efficiency

Separate quality inspectors, receivers, and production personnel to avoid the possibility of corruption.

Reduce the number of quality inspectors, improve quality inspection efficiency, and achieve cost reduction and efficiency improvement.

03

Traceable incoming materials

Traceable quality information of incoming materials, easily manage suppliers. The system data is clear at a glance and can monitor quality inspection data in real-time, allowing the boss to accurately grasp it no matter where they are.

Pay for the Residues? No way! DataBeyond can help you better resist market cyclical fluctuations!